Jay Kipper and Sean Murphy on nanotechnology in oil and gas production

Nanotechnology – that is, working with matter at the scale of atoms and molecules – shows great promise for meeting challenges involved in understanding and utilizing the harder-to-reach oil and gas reservoirs of today. That’s according to scientists at the Advanced Energy Consortium (AEC), a research organization that develops micro- and nano-sensors to transform understanding of subsurface oil and natural gas reservoirs. The University of Texas at Austin’s Bureau of Economic Geology at the Jackson School of Geosciences manages the AEC. Two AEC scientists, Jay Kipper and Sean Murphy, spoke with EarthSky about how the success of nanomaterials in diverse fields such as medicine and automotives is being applied to petroleum science.

Let’s begin with some basics. What is nanotechnology?

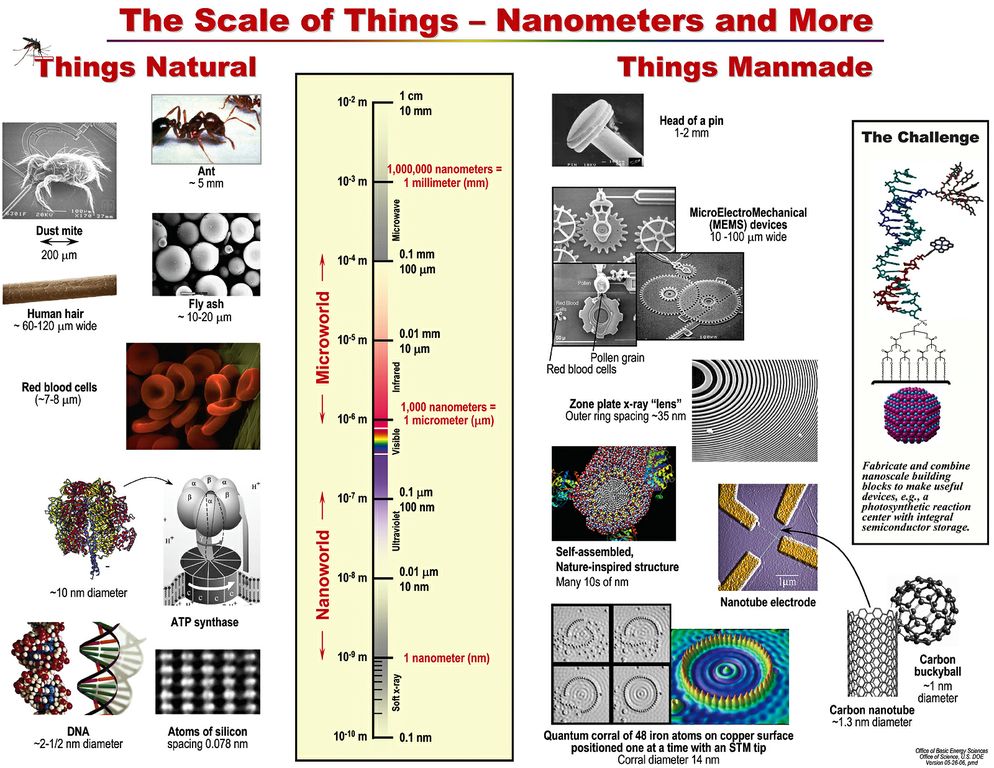

Jay Kipper: The prefix nano, from the Latin word nanus for dwarf, means something very small. When we’re using it in metric terms, a nanometer is one-billionth of a meter. Think about that! Take a strand of hair and put at it between your fingers. The width of that hair is 100,000 nanometers. If you put three atoms of gold side-by-side, that’s a nanometer in width. A nanometer is about how much your fingernail grows every second. So a nanometer is really small. It was IBM in the late 1980s that invented the scanning tunneling microscope needed to image individual atoms that really initiated the field of nanoscience. Today, you might say nanotechnology is the application or use of nanoscience to manipulate, control and integrate atoms and molecules to form materials, structures, components, devices and systems at the nanoscale – the scale of atoms and molecules.

Why is the oil and gas industry interested in nanotechnology?

Jay Kipper: There are a couple of answers to that question. First, looking at it from the perspective of science, what’s really intriguing and fundamental about nanomaterials and nanotechnology is the size of the materials that we’re studying. The incredibly small size of these nanoscale materials creates opportunities for them to be injected into oil and gas reservoirs.

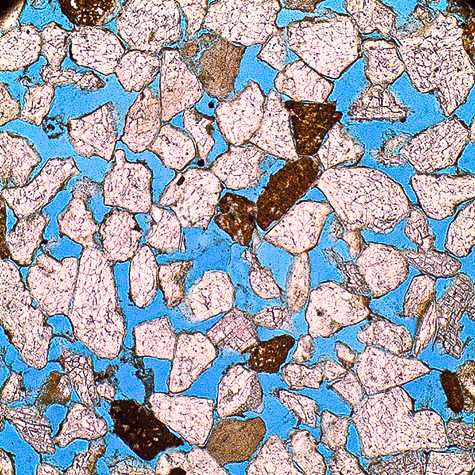

As readers know, oil and gas is commonly found in rocks that are buried thousands of feet underground. These rocks are constructed like sponges. Even though a rock might look like it’s solid, it really has many pathways for fluids to flow through freely. The spaces between these sand grains and cemented grains are called pore space and pore throats by geoscientists. Geoscientists have analyzed enough of these oil-bearing sandstones to establish that the pore throat openings commonly range between 100 and 10,000 nanometers in width. That’s large enough for fluids like water, brines, and oil and gas to flow through relatively freely. So if we could put nanoscale tracers or sensors down a hole, they would be small enough to flow through these pores, and we could gain a bunch of valuable information about the rock and the fluid environment where the oil and gas is found.

What’s exciting about nanoscale materials is that, chemically, they behave differently from bulk materials. They’re sort of magical in many ways. For example, dropping metal powders into water results in all the particles sinking to the bottom or floating to the top, but stable nanoparticles stay in suspension in the fluids, and that’s very different from what one might expect. Industries take advantage of these different properties. Nanoparticles in tennis rackets and snow skis enhance their strength. We use nanoparticles of zinc oxide or titanium dioxide in sunscreen to more effectively absorb the ultraviolet light rays and protect the skin. Nanoscale silver is an effective antibacterial agent and is woven into fabrics and clothes to keep them from smelling.

Tell us more about the use of nanotech in the oil and gas industry.

Sean Murphy: Well, unless a revolutionary new source of energy is developed or discovered, it appears that we are going to be dependent on hydrocarbons for the foreseeable future. Even the most optimistic and realistic scenarios of renewable energy sources project that wind, water, solar and geothermal will only make up 15% to 20% of our total energy by 2035. So it’s clear that we’re going to rely on hydrocarbons like oil and gas to be important bridge fuels.

What’s often not appreciated by the public is how much oil is left behind in the oil fields. When oil is first tapped in a new oil field, the oil typically flows freely from the production wells for the first few years just based on the inherent pressure in the reservoir. This primary recovery, also called pressure depletion, is carefully monitored and managed. But at some point, the pressure is depleted to the point at which the production rates have declined significantly, so petroleum engineers resort to using some sort of external energy to increase the pressure. Most often this involves injecting water (or more commonly reinjecting water that’s already been produced from this field) to increase the pressure and drive oil from the injection to production wells. This step is called secondary recovery. When finally even this step in the process fails to produce enough oil, then the owner has to decide if it’s worth applying other, more expensive means of improving the oil recovery. They look at things that are more exotic like steam, gases like carbon dioxide or detergents to break free the remaining oil that’s binding to the rocks and keeping it in the reservoir.

Even after all of these enhanced oil recovery steps (primary, secondary and tertiary) have been taken, it is still not uncommon for 60 – 70% of the original oil to be left in the reservoir. So, if you think about that, there are billions of barrels of discovered oil that we’re leaving in place.

I’ll give you an example that’s close to home here in Texas. The U.S. Department of Energy did a study back in 2007 that estimated that there are at least 60 billion barrels of oil remaining in the Permian Basin, which is on the border of west Texas and New Mexico. Remember, these aren’t undiscovered oil fields, or deep water fields, or unconventional oil fields. This is oil that’s left behind in existing fields with existing infrastructure. These recovery rates are determined by a number of interrelated issues, things like permeability of rocks, viscosity of oils and drive forces in the reservoir.

One of the primary reasons that the oil remains unrecoverable are the capillary forces that bind or adhere the oil molecules to the rocks. This isn’t really that difficult a concept, and I can demonstrate it simply. One analogy is simply trying to remove an oil stain from your driveway. This is the adhesion problem. It’s probably just several molecules of absorbed oil. Now, take a sponge and fill it full of water. Squeeze it out into a glass and see how much water was absorbed. Now soak the sponge again, and try sucking out the water in the sponge with a straw. It’s much harder, isn’t it? That’s analogous to what we’re trying to do in an oil field, except that oil also adheres to the pores in our rock sponge.

So at this point, knowing that there are billions of barrels of remaining oil in place, the oil industry is looking for more effective ways to improve the recovery rates. Nanomaterials are an obvious place to look. Because of their small size they can conceivably be transmitted through the rock and the oil fields along with injected fluids, and because of their high chemical reactivity, they can be used to reduce the binding forces that hold the hydrocarbon molecules to the rocks.

What’s really exciting about this is that even small improvements in the recovery rate can result in millions of gallons of additional recoverable oil. It’s technology like this that could make energy affordable for consumers in the future.

Tell us about nanoscale sensors. We hear they are a very powerful tool.

Jay Kipper: Yes. Here at University of Texas Bureau of Economic Geology, we’re focusing on the concept of making nanomaterial or nanoscale sensors.

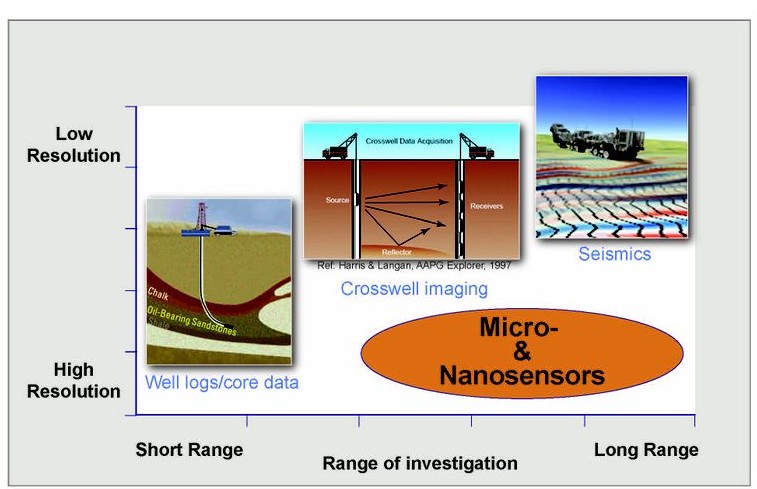

Right now, the industry has three ways to “interrogate the field,” that is, to see what’s going on underground. They first drop connected geophysical electronics down the well to measure things that are going on very close to the well bore. A second way to interrogate the field is through cross-well tools. In this process, a source and receiver are placed in the injection and producing well hundreds of meters down hole and apart from one another. They are able to communicate with one another through seismic and conductive tools, but the resolution is only meters to tens of meters in quality. The big workhorse of the industry is surface seismic, which use very long wave sonic pulses that penetrate deep into the earth to determine the general structure of the subsurface rocks, but the resolution again, is typically tens to hundreds of meters.

So here’s the opportunity with nanoscale sensors. We can inject them into the oilfield to get deep penetration into the wells, and high resolution because of the unique properties of the nanomaterials.

In other words, using nanotech lets you get a clearer view of what it looks like down hole?

Jay Kipper: Right. An analogy that Sean and I often use is the human body. Right now, doctors are working to put nanosensors into the human body to determine where cancer cells might be, for example. Here, we’re looking into the Earth body. We’re putting nanosensors down hole and getting a better idea of what’s going on. Right now, in geology and petroleum engineering, we interpret or make best guesses as to what’s going on. What the nanoscale sensors will give us is a better idea, more data, so we can make smarter interpretations, and get a better idea of what’s going on down hole. And with a better idea of what’s going on underground we’ll be able to recover more hydrocarbons. That’s going to be huge for the industry and the world.

How do advances made in nanomedicine apply to oil and gas wells?

Sean Murphy: Many of the researchers who are funded to do research by the AEC are also working on nanomedicine projects. Over the last four years, we’ve come up with two classes of sensors that have their origins in the field of medicine.

We are working on a class of sensors that we have dubbed contrast agents. The concept is similar to MRI, or magnetic resonance imaging, which is a common medical imaging technique used to visualize internal structures of the body in detail. MRI makes use of the property of nuclear magnetic resonance (NMR) to image nuclei of atoms inside the body so we can differentiate organs. We are essentially looking at scaling up this technology to the size of a reservoir using magnetic nanoparticles and a large magnetic source and receiver. We’ve mentioned that the oil industry injects recycled water into the oil field to improve oil recovery, we call that secondary recovery. What’s surprising is that the reservoir engineers really don’t know much about where this water is going. They use chemical tracers, and can detect when these show up in the producing wells, but they have to guess what the flow streams look like as this injected fluid moves through the reservoir. With the technology that we are working on, it may be possible to co-inject nano-sized magnetic particles with the injected water and monitor exactly where the water travels through the reservoir. The potential impact is huge for recovering more oil. With this information petroleum engineers could identify areas that are bypassed and target these areas more directly, either by adjusting their injection pressures or possibly by drilling additional, more targeted wells.

Another class of sensors that we are developing are called nanomaterials sensors. Many of the approaches that we are using are also derivative from medical research. I’m not sure if you’ve heard about the latest in cancer research, but it looks like doctors may soon be able to remove tumors and cancer cells more directly without harming the patient like we do today with chemical and radiation treatment protocols. Researchers are now targeting cancer cells with cancer-specific binding molecules that attach directly to the cells, and carry along metal nanoparticles. These metallic nanoparticles can be irradiated, resulting in localized heating up of the metal particles and burning off the cancer cells without harming the surrounding healthy cells or tissue. Some of our researchers are adopting this same strategy to target oil molecules and deliver chemicals directly to the oil and hydrocarbon particles to reduce the interfacial forces that bind the oil to rock surfaces. Essentially this is a targeted enhanced oil recovery system, which is potentially much more efficient and could significantly reduce the amount and type of chemicals that are injected during a tertiary chemical recovery flood.

Another concept that is just being explored and that draws from medicine is the adoption of technologies that are used in time-release medicines and capsules. In the body these are used to deliver uniform doses of medicine over a longer time frame, or to target delivery of the medicines to specific areas of the body, like the lower intestine. A couple of our researchers are developing nanostructured coatings that degrade at predictable rates under the high pressures and temperatures and the harsh chemistries that we see in the oil field so that we can time the delivery of chemicals or tracers to different parts of the reservoir. This is really challenging, because no one has ever thought of using nanoscale capsules as engineered long range delivery systems. It’s pretty intriguing.

Looking ahead, what’s the most promising research in nanotechnology that you see bearing fruit for the oil and gas industry?

Jay Kipper: We’re developing whole new class of sensors that we have called microfabricated sensors. We see them as long-term, but revolutionary. We want to push down the size and reduce the power consumption of microelectronics even more than the semiconductor industry has accomplished to date. The progress to date has been tremendous. We’re all walking around with iPhone and smart phone computers in our pockets with computing power that used to fill a large room in the early days of computing. But to make electronics relevant for the oil and gas industry, we need to shrink integrated sensor devices down in size from the millimeters sizes today to the micron scale in the future.

Right now we’re funding a project to take a number of sensors that our researchers have created over the last four years and integrate them on a one-millimeter cubed device, including sensors, processing, memory, clock, and a power supply. This is small enough that it could conceivably be used as an untethered sensor floating around in an oil well collecting data, or injected in between the sand or proppants that are used in frack jobs today. Our researchers have to take clever and non-intuitive approaches to make this happen. They are shedding functionality, reducing the number of measurements from thousands per second to one or two per hour, or per day. That reduces the memory size required, and the power requirements. Researchers have invented new materials for batteries that can survive at very high temperatures (greater than 100 degrees C). It’s incredibly exciting research! What that means to consumers is that if we can recover more hydrocarbons, that means more energy, and more energy is a good thing for society.

What’s the most important thing you want people today to know about nanotechnology in the future of oil and gas production?

Sean Murphy: I think nanotechnology is incredibly exciting and it’s applicable to almost all product industries. If I were a student in school today, it’s the field that I would be studying. On one hand, it’s a natural evolution from our technology drive to miniaturize our tools and implements. On the other hand, the future impact of nanotechnology on our lives is going to be revolutionary.

And we’re just at the beginning of this creative revolution.

In the oil and gas industry, nanoscience and nanotechnology may enable us to sense remotely and directly the bypassed oil and gas that we could never see before. And with the sensors we’re developing to provide us with more information, we’ll be able to recover even more oil and gas that right now is being abandoned and left in the ground. New nanomaterials will revolutionize other energy fields like solar and storage and transmission and waste remediation. It’s really exciting.

To maintain our quality of life, we’re going to continue to need affordable, safe and secure energy. Nano is one of the new revolutions in technology that will make that happen.

Jay Kipper is Associate Director at the Bureau of Economic Geology at the Univerity of Texas at Austin. He and Scott Tinker lead the research effort and set the strategic direction for the AEC. Kipper is also responsible for all operational and financial aspects of the Bureau. Jay got his BS in Engineering from Trinity University in San Antonio and worked 20 years at various companies in the private industry including SETPOINT and Aspen Technology before coming to the University of Texas.

Sean Murphy is currently responsible for a team of Project Managers who oversee 30+ individual research projects at leading universities and research institutes around the world, including several here at the University of Texas at Austin. Sean Murphy began his career as a geologist in Texas in the early 1980’s, drilling the Hockley salt dome near Houston for Marathon Resources in search of base metal sulfides. Then he moved to Austin and worked in the semiconductor industry for 23 years, first for Motorola, then SEMATECH. He has degrees in Geology from the College of William and Mary in Virginia and the University of Georgia, and an MBA from the University of Texas.